Vial Crimper | China Factory - KAYUXU

8mm 13mm 15mm 20mm 28mm 32mm caps

vial crimper and decapper by handheld, auto, used for pharmaceutical, food, packaging, chemical industry, laboratories, perfume etc.

Inquire Now

Descriptions

Vial Crimper & Decapper

| Item No | Used for |

| PT15 | 15mm sprayer perfume bottle |

| PT8 | 8mm aluminum cap on glass cartridge |

| PT11 | 11mm aluminum central cap on sampling bottles |

| PT13-A | 13mm aluminum crimp cap |

| PT13-B | 13mm plastic-aluminum flip off cap |

| PT20-A | 20mm plastic-aluminum flip off cap |

| PT20-C | 20mm aluminum crimp cap |

| PT28-A | 28mm aluminum crimp cap |

| PT28-B | 28mm plastic-aluminum flip off cap |

| PT32 | 32mm plastic-aluminum flip off cap |

Vial crimper sealing capping machine

1 piece for each size, use to crimp cap of different size, need extra head.

PT8, PT11, PT15, PT13-A, PT13-B, PT20-A, PT20-C, PT28-A, PT28-B, PT32 is common size,

for custom size, can be made according you requirement.

| Image | Name | Specification | More |

|

Handheld steel vial crimper | Overall size: 180 * 120 * 500mm Weight: 0.6 kg Power: manual hand held Material: the best stainless steel |

|

|

Handheld CFRP vial crimper | Overall size: 180 * 120 * 500mm Weight: 0.4 kg Power: manual hand held Material: the best stainless steel for crimp head,aerospace composite materials (CFRP) for handle |

|

|

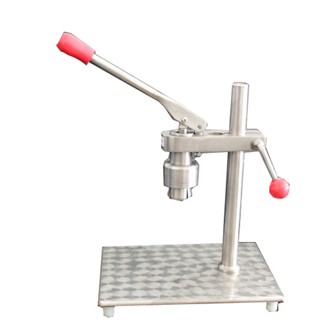

Table stand vial crimper | Overall size: 260 * 200 * 330mm Weight: 4.5 kg Power: manual table stand Capacity: 30-50 bottle/min |

|

|

Auto vial capping machine | Overall size: 580 * 300 * 650mm Weight: 45 kg Power: auto / electrical Capacity: 380v/ 220v, 50hz |

|

|

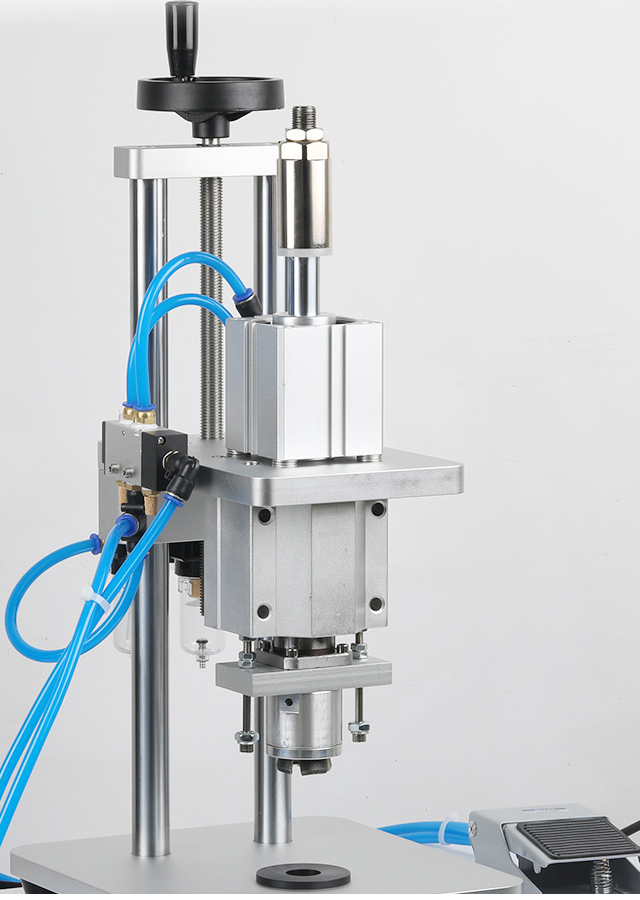

Pneumatic vial capping machine | Overall size: 270 * 250 * 490mm Weight: 18.5kg Technical Data: Applicable bottle size: 90-100mm (Height), 45-55mm (Dia), 20mm (Mouth dia) Working Method: Fully Pneumatic Air Source: 0.4-0.6MPa Torsion: 4~8kg/cm (standard) Speed: Min. 30 bottles/minute Power supply: 220/240 VAC, 50 Hz, 1 ph. |

Guarantee: Min. One year. Installation: To be done by the supplier at his own cost. After service: Min. two years. To be supplied complete with air-compressor & other necessary accessories to run the machine. |

|

|

|

usage method: step1: put stopper onto vial step2: put flip off cap onto vial step3: take the crimper in your hand step4: put crimper onto flip off cap step5: press the handle step6: check the effect, if the cap can slip, then check step7. step7: if the cap is loose, just adjust the claw, then crimp the cap again. (adjust the claw from clockwise direction to loosen, and from inverse direction to tighten) |

features:

all stainless steel casting material. beautiful and generous workmanship can pressure of various of bottles, oral liquid etc. good sealing, rolling out of the smooth, preise. long handle design, operation more effort |

| crimper |

(1) handheld crimper (2) tabletop crimper (3) electric crimper capping machine (4) pneumatic crimper capping machine |

| filling |

(1) manual filling machine (2) semi-automatic filling machine (3) automatic filling machine (4) automatic filling and sealing machine (5) automatic filling and capping machine |

| labeling |

(1) manual labeling machine (2) semi-automatic labeling machine (3) automatic labeling machine |

| tablet |

(1) round tablet mold (2) irregular tablet mold (3) ZP tablet mold (4) manual tablet machine (5) automatic tablet machine |

| date coder |

(1) automatic date coder machine (2) semi automatic date coder machine (3) manual date coder machine (4) date coder machine accessories |

Product Description

Related Products

Inquiry Now

Please give us a message for your enquiry . order or advice. Thanks a lot.

Send Message